Chad Pippin

Site Supporter

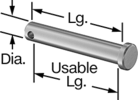

Good short term fix, but over time the threads will wollow out the holes as they abrade them with use. I was thinking of recommending either a shoulder bolt - less common than the pins I recommend - or a bolt with an unthreaded length to act as a bearing surface, but that may be had to find in that diameter. Plus, such bolts tend to be threaded the entire length until they get really long and then the unthreaded length is difficult to spec. And you'd want to cut off the unused portion.Nut and bolt?

Shoulder bolts are not easy to come by retail in my experience as you wrote. I usually need to order them online and the shipping costs five times as much as the shoulder bolt. Purpose made pins are not always easy to come by in retail stores in the diameter that one might need either.Good short term fix, but over time the threads will wollow out the holes as they abrade them with use. I was thinking of recommending either a shoulder bolt - less common than the pins I recommend - or a bolt with an unthreaded length to act as a bearing surface, but that may be had to find in that diameter. Plus, such bolts tend to be threaded the entire length until they get really long and then the unthreaded length is difficult to spec. And you'd want to cut off the unused portion.