DaveWooster

'95 ST1100ALS and '98 Standard ST1100W

I bought an ST1100 "carb assembly" by mail order. Not having a mechanic available at this time, I went about getting the gasoline out of it myself.

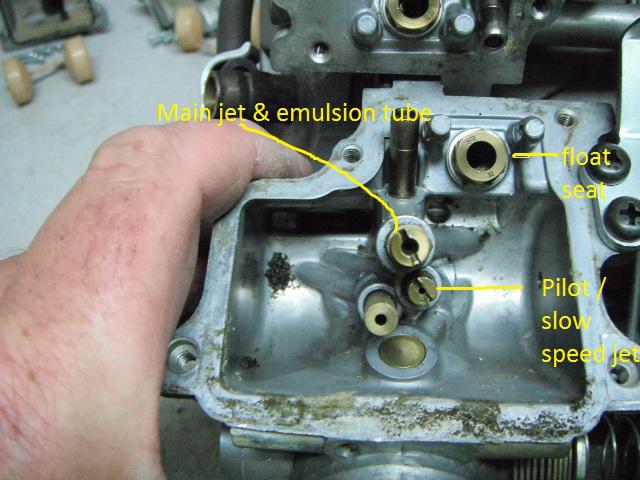

I opened the float bowls; unscrewed the Slow Jets; and cleaned them with mineral spirits (not having any carb cleaner on hand).

The Main Jets looked similar, having a slot for a flat bladed screw driver. So I took two of them out and cleaned them. (Let me know if you need photos to follow this.)

Trying my luck on the third Main Jet, the two-piece nature of those Main Jets came to my attention. All that I removed was the small head portion, which is like an ordinary machine screw with a flat head. The Jet itself remained in the carb. (It has a hex portion on it so that it can be removed with a wrench or spanner. I repeated my "mistake" with the fourth and final Main Jet.)

Is that head portion there for adjusting that Main Jet? (If so, I have put that Jet out of adjustment.)

Or is it there just to make installation of the Main Jet easier?

What do you think?

(And down the road ahead: Has anyone written up a reasonably simple procedure for cleaning a carb assembly that is off the bike?)

Here are the details, for your reference:

American - California carb assembly number 16100-MY3-690. It came off of a 1994 ST1100ALR ABS model, but that assembly is also used on California non-ABS ST1100s starting with 1993, or maybe 1992.

Slow jet number 38S, and

Main Jet number 125.

I opened the float bowls; unscrewed the Slow Jets; and cleaned them with mineral spirits (not having any carb cleaner on hand).

The Main Jets looked similar, having a slot for a flat bladed screw driver. So I took two of them out and cleaned them. (Let me know if you need photos to follow this.)

Trying my luck on the third Main Jet, the two-piece nature of those Main Jets came to my attention. All that I removed was the small head portion, which is like an ordinary machine screw with a flat head. The Jet itself remained in the carb. (It has a hex portion on it so that it can be removed with a wrench or spanner. I repeated my "mistake" with the fourth and final Main Jet.)

Is that head portion there for adjusting that Main Jet? (If so, I have put that Jet out of adjustment.)

Or is it there just to make installation of the Main Jet easier?

What do you think?

(And down the road ahead: Has anyone written up a reasonably simple procedure for cleaning a carb assembly that is off the bike?)

Here are the details, for your reference:

American - California carb assembly number 16100-MY3-690. It came off of a 1994 ST1100ALR ABS model, but that assembly is also used on California non-ABS ST1100s starting with 1993, or maybe 1992.

Slow jet number 38S, and

Main Jet number 125.

Last edited: