dmulk

Dan Mulkiewicz

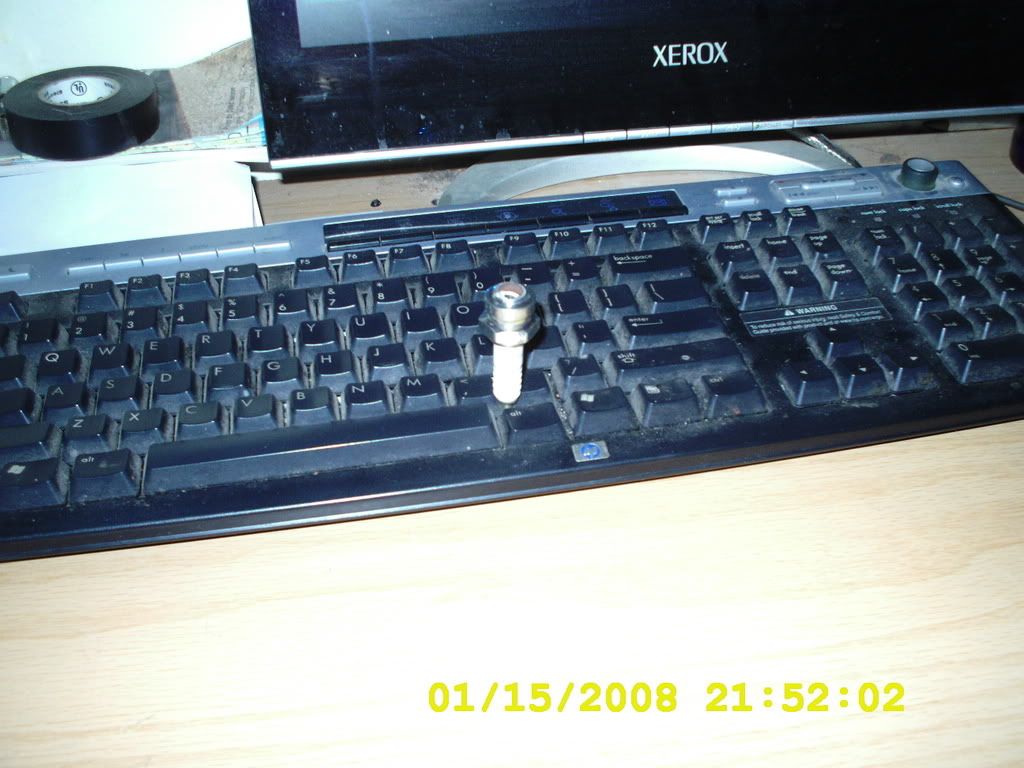

If this isn't your only mode of transportation, I'd pull the head.

Even if you get it out, you are always going to wonder if there are bits of ceramic floating around in there....

You might get a kick out of doing this work on the engine yourself. It's not too hard with the right manual. I know it looks bleak, but just take your time and try to make it a fun experience.

<D>

Even if you get it out, you are always going to wonder if there are bits of ceramic floating around in there....

You might get a kick out of doing this work on the engine yourself. It's not too hard with the right manual. I know it looks bleak, but just take your time and try to make it a fun experience.

<D>