That is exactly what I did on my current bike.

BUT... and this is the most important bit... make sure the cable is 16 ga or bigger wire. The typical Battery Tender cable is only 18 ga (smaller wire) and really shouldn't have more than 10-12 amps running on them. Reminder: smaller ga number means bigger sized wire.

Of course, length of the round trip run from + to - is also a factor (from battery positive post all the way out to the load and BACK to the battery negative post) but not knowing for sure if you'll have a short run it's better to be safer with the bigger ga wire.

When I run wire on my bikes I'll use 18 ga for anything that will be no more than 5-10 amps and 16 ga for 15-20 amps. The link I posted earlier is a 16 ga cable set.

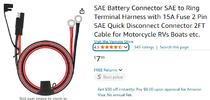

If desired, here is a link to a cable set that is 10 ga that will handle up to 30 amps and even comes with a gender changer.

https://a.co/d/90sIUOB