Expand above.Quick note on that: Check it before and after the ride. If residual air gets trapped in this area, the SMC may not fully spring back after you manually compress it and cause problems.

But it looks like Honda has done a better job on the GL than on the ST to eliminate the trap.

I went ahead and checked the pivot bracket along with pivot action once again on the SMC. As shown in the video below, the SMC is pivoting but, not by much. I'm sure that's the most that it would with the wheel off the ground and by hand under hydraulic pressure. I checked the 69mm oem measurement again of the SMC push rod length which was spot on. The outer copper collar flange on the pivot arm for the SMC is a little rough on one side but, it's been that way for years from one of my first tire changes. It has never affected the inner steel collar for free piston arm rotation. I would have changed this flanged collar but, its not replaceable that I can see of. One thing I find odd, the SMC piston rod is on an angle when mounted to the caliper bracket (pic below). With the caliper bracket removed, it hangs straight. All mounting points for the caliper bracket and SMC are in great shape with no slop/wear. I've never noticed this before but, I've never taken a good look until now. Obviously, it correct but, I'd rather see it straight.

YT SMC Video:

Well....from this info , it sounds like there may not be many Monarch 1s left on the road with Drums: You could be the last one standing!

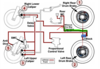

And not surprisingly. This is not a very good design on the hydraulic side. The pedal on the GL was governing only 1/3 of the rear braking power (one out of three pistons), and now on the Trike it has full power on drums that are harder to modulate than disks. Doesn't make much sense.

You could say they could have installed a smaller diameter MC to compensate, but you don't want to do that because it also operates 1/3 of the front braking power and you do not want to lose any of that for emergencies.

It was a small period that Lehman used drum brakes before they switched. With that being said, I've never had any issues along with always having great braking no matter what weather or situation I was in. Back then a lot of people preferred drum brakes over disc mainly due to wet weather.

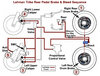

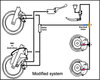

You may want to update your hydraulic schematic to show the Wilwood on the correct line, the pedal to drum line, as shown on the pics you posted. It will help to follow the not so simple SMC braking process.

I will... That I wasn't sure about until now, it makes total sense thanks to your explanation below. I thought the Wilwood one-way valve was an addition coming from the PCV to help aid the functionality of the rear drum brakes. Sooo oblivious.....

Because of the WIlwood check valve in the pedal brake line, the brake fluid to the rear has to go back to the rear reservoir le long way around, via the SMC, the WIlwood prevents fluid to go back to the rear reservoir through the pedal line , regardless if the drums are activated by the SMC OR the Pedal. It makes no difference to the drums where the pressure is coming from, all they see is a pressure increase at the J-Block. They will react the exact same way if the pressure comes from the SMC or from the Pedal. They have no more reason to drag when you apply the rear than when you apply the front (unless of course the pedal is not fully released, it sometimes happens inadvertently).

So there is no reason to suspect the pedal is responsible for the drums dragging. For locking them up, for sure, as the pedal delivers too much pressure for the drums and doesn't have a pressure limiter, like the PCV in the SMC line.

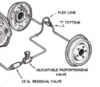

My thought now is even more so in leaning towards the PCV for a possible solution. Once I receive the PCV and get some time, I'll have to remove a lot of plastic, drain the entire hydraulic and cooling system for the install (winter project). This time with it drained, I'm going to remove the J-block and check for obstruction as well. As far as I know, it's only a J-block. With that being said, I'm going to have to order some banjo bolt crush washers. I would chase the hydraulic lines first starting at the rear wheel cylinder followed by the J-block, PCV.... if I could lock them up while mobile. So far I haven't been able to do that.

And every time you use the front, the rear is automatically applied, want it or not, the SMC will do it for you. And not only that, the SMC will apply more braking power you had on the GL, as the SMC was only affecting 2/3 of the rear brakes (2 pistons out of 3) vs full power on the Trike. So your rear Trike brakes see more intense use than they would on the GL.

For sure.... Always had great stopping power when needed.

There is one "relatively easy" test you could run to see how well pedal pressure bleeds back to the rear reservoir via the SMC. with the Trike immobilized.

You could disconnect the line at the rear MC that goes to the front and plug the corresponding port on the MC.

I'm not sure where the T is from the MC due to it being buried, not seeing it visually. As in the diagram, one line T's off to the Delay Valve with the other line leading to the Wilwood valve then J-block. Please correct me if I'm wrong, I believe you would want me to disconnect the line leading to the Delay valve at the T and then plug it off where I disconected it. The fluid would then flow out of the delay valve line.

Then, when you press the pedal, you should see fluid coming out of the disconnected line .....if it all works correctly.

The pedal should also stay down as the Wilwood should prevent fluid coming back to it.

Another thing to check, is that your front left caliper releases completely, not causing excessive drag and unsolicited SMC activation.

I did clean up the calipers and pistons in which they are/were working properly with the front end jacked up. Of course this test was done with the trike being mobilized along with observing visually while applying the front lever and rear pedal with and without the pads in place. I didn't take apart the calipers due to all realeasing properly....

Without doubt, you have given me a much clearer picture, especially with pointing out the proper placement of the Wilwood valve. It's all making more sense to me which more than helps as I move forward. I'll definitely revise/correct my diagrams and post them back & please, feel free to straighten me out if you see me slipping into oblivia.. LOL!

I can't Thank You enough for taking the time in helping me out in explaining how this hydraulic system works along with some tests to perform. I sincerely appreciate it!! Thank You!! Ray