What is everyone using for lube to install tires?:tb1:

Honda spray cleaner

What is everyone using for lube to install tires?:tb1:

What is everyone using for lube to install tires?:tb1:

I

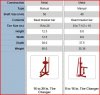

Description says manual mount/demount. Only the clamps and the bead breaker are air operated?

To change tires I use a Slippery STuff recipe:

Murphy's oil soap

Antifreeze

Water

But I can not find my recipe for the proportions right now.

What is everyone using for lube to install tires?:tb1:

What is everyone using for lube to install tires?:tb1:

It works well. I bought a Cycle Hill

Curious......... If it works well why the switch?

Several reasons..... the Cycle Hill was on sale for $295...