woodybelle

Site Supporter

Doesn't tip over switch activation require you to cycle the ignition to get it to restart?

So Mark are you saying there's a loss of 12V power only to the ECU somehow?

So now that I have that straightened out, do you think its worth swapping around a few fuses to see if the symptom goes away, or elsewhere? I'm wondering if you could somehow have a marginal fuse that vibrates open at the critical RPM and then reconnects a split second later. Or a marginal connector in that path.

I keep harping on watching the ECM supply line because a drop or sag immediately rules out a lot of hard-to-diagnose things and points in the direction of things that are very easy to run down. There's no reason to guess at it when you can find out one way or the other through measurement.

You deleted the part of my post where I asked if there is an accessible point at which the measurement can be taken. I don't have a 1300, so its not obvious to me. Since you keep saying do it, but not how to do it, does that mean to the average 1300 owner that the monitoring point for the ECM power supply is obvious and easily accessible?

The +12vdc circuit that supplies voltage to the ECM can be found in the RED Service Connector (Black/White conductor), located beneath the right side (brake lever/pedal side), of the pillion seat.an accessible point at which the measurement can be taken.

Since you keep saying do it, but not how to do it, does that mean to the average 1300 owner that the monitoring point for the ECM power supply is obvious and easily accessible?

The +12vdc circuit that supplies voltage to the ECM can be found in the RED Service Connector (Black/White conductor), located beneath the right side (brake lever/pedal side), of the pillion seat.

Perhaps instead of trying to position, and read a voltage meter at speed, installing a LED lamp in the circuit, and locating the LED lamp where it can be monitored by the operator would be safer.

The advantage of the LED is that it draws a miniscule current load, which should not skew the test results, also the LED lamp does not suffer from filament shut-off lag, such that even a voltage drop of short duration will be noticeable.

Yes, it does. The black/white wire on the diagnostic connector in the back of the bike is tapped from the same circuit that supplies the ECM. The ideal thing would be to slip a needle probe into the ECM connector where that wire lands, but the diagnostic connector is close enough to at least get us pointed in the right direction.

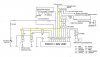

The circuit we're looking at is the one highlighted in this picture:

The diagnostic connector isn't shown here, but it is on the wiring diagram. Note that this circuit also supplies the low side of the ignition coils.

--Mark

Perhaps instead of trying to position, and read a voltage meter at speed, installing a LED lamp in the circuit, and locating the LED lamp where it can be monitored by the operator would be safer.

The advantage of the LED is that it draws a miniscule current load, which should not skew the test results, also the LED lamp does not suffer from filament shut-off lag, such that even a voltage drop of short duration will be noticeable.

Maybe a broken wire somewhere which is a tough one.