Hi question I have a problem doing the fork seals on my ST1100. Can I change the seals with removing the hex bolt at bottom of fork ? It looks like the previous person who did the job has chewed up the head if that makes sense

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

St11000 Fork Seals

- Thread starter pete1960b

- Start date

I'm pretty certain the seal replacement can only be done with the slider removed from the stanchion. Which does require removal of that bolt.Hi question I have a problem doing the fork seals on my ST1100. Can I change the seals with removing the hex bolt at bottom of fork ? It looks like the previous person who did the job has chewed up the head if that makes sense

Are both, or just one, buggered up?

This would be a good opportunity to replace the seals and those bolts at the same time. There are techniques for freeing a socket head bolt you can employ. Finding the 3/8" drive torx socket size just larger than the proper hex and hammer it into the socket at the head of the bolt essentially acting like a broach to form new surfaces to grip.

Prepare to use heat to help weaken the threadlock that was likely used on that bolt. I recommend a heat gun, rather than a torch, and raise the temp slowly to minimize potential damage to the paint on the sliders.

But, I also used my last seal replacement as an opportunity to repaint the lowers. I used VHT Roll Bar and Chassis Paint that worked quite well and has held up through road use.

Uncle Phil

Site Supporter

If you have it available, an air ratchet sometimes can break it lose if you can get on it.

Many thanks only just removed the forks and it looks like one is churned up will have a look in morning many thanks Phil...Also one other question my forks have a very large allen key at the top of the fork is this a dust cap ?I'm pretty certain the seal replacement can only be done with the slider removed from the stanchion. Which does require removal of that bolt.

Are both, or just one, buggered up?

This would be a good opportunity to replace the seals and those bolts at the same time. There are techniques for freeing a socket head bolt you can employ. Finding the 3/8" drive torx socket size just larger than the proper hex and hammer it into the socket at the head of the bolt essentially acting like a broach to form new surfaces to grip.

Prepare to use heat to help weaken the threadlock that was likely used on that bolt. I recommend a heat gun, rather than a torch, and raise the temp slowly to minimize potential damage to the paint on the sliders.

But, I also used my last seal replacement as an opportunity to repaint the lowers. I used VHT Roll Bar and Chassis Paint that worked quite well and has held up through road use.

Uncle Phil

Site Supporter

Hmm, usually it is a very large nut, makes me wonder if the PO installed the fork caps upside down.Many thanks only just removed the forks and it looks like one is churned up will have a look in morning many thanks Phil...Also one other question my forks have a very large allen key at the top of the fork is this a dust cap ?

If you remove that, the 'guts' will want to push upward so be careful.

I also suggest you loosen it while the forks are still in the triple tree.

Otherwise trying to get a grip on the forks to hold them so you can loosen it is a bit of an 'interesting' situation.

You sure about that, UP?Hmm, usually it is a very large nut, makes me wonder if the PO installed the fork caps upside down.

I'm certain my 91 1100 has a hex socket in the fork cap. I dressed them up with the rubber caps from a 90s era Nighthawk 750 after I ditched the handlebar cover and painted the top triple clamp.

I want to say it's a 12mm but I'm away from the garage at the moment. I'm fairly sure it's the same hex wrench for the 1300 as well.

17 mm hex (allen) on mine. Plastic caps and also a ditched cover hunk of plastic!

Uncle Phil

Site Supporter

Some days I ain't sure of even who I am til I look at my driver's license!You sure about that, UP?

I'm certain my 91 1100 has a hex socket in the fork cap. I dressed them up with the rubber caps from a 90s era Nighthawk 750 after I ditched the handlebar cover and painted the top triple clamp.

I want to say it's a 12mm but I'm away from the garage at the moment. I'm fairly sure it's the same hex wrench for the 1300 as well.

Hmm, all of mine are 97 or later so maybe they changed the fork caps.

Or it could be on 43mm ABSII forks they have them installed the 'proper' way ...

Uncle Phil

Site Supporter

Well, y'all made me get my lazy bones up and go take a look at my 2 ABSII spare ST1100s.

Since 3 of 4 of my runners were ABSII originally, and I converted my one standard forks quite a while back,

I did not remember the 'other' style fork caps.

Evidently when Mother Honda went from the 41mm to the 43mm forks for the ABSII they changed the fork cap design also.

Since 3 of 4 of my runners were ABSII originally, and I converted my one standard forks quite a while back,

I did not remember the 'other' style fork caps.

Evidently when Mother Honda went from the 41mm to the 43mm forks for the ABSII they changed the fork cap design also.

That's a nuance of the changes to the second gen ABS II that I hadn't encountered. Will tuck that factoid away never to be remembered until some 'ST Trivia' competition at a future STOC gathering!Well, y'all made me get my lazy bones up and go take a look at my 2 ABSII spare ST1100s.

....

Since 3 of 4 of my runners were ABSII originally, and I converted my one standard forks quite a while back,

I did not remember the 'other' style fork caps.

Evidently when Mother Honda went from the 41mm to the 43mm forks for the ABSII they changed the fork cap design also.

Actually, loosen the upper clamps, or they'll make it harder to loosen the caps.I also suggest you loosen it while the forks are still in the triple tree.

And yes, the non-ABS models have 17mm socket heads, not hex heads.

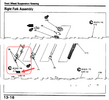

Loosen the top triple clamp bolts, then break the fork caps loose. Its a 17mm allen head on the standard, don't know what size those are on the ABS2. Don't remove the caps, just loosen them, then remove the entire fork assembly from the triple clamps.

After removing the forks then break the bottom bolt loose. An impact driver can help, but in my experience they usually break loose just using a regular ratchet. If they're buggered up then maybe the Torx idea will work if you're lucky. Otherwise it may be a case of drilling the head off and trying to extract the remaining screw from the fork lower. Also, the screws are recessed into the fork lower far enough that a regular length hex drive socket won't usually reach, so you'll need a long reach hex socket, or make one yourself. I think its 6mm hex drive, but my memory is weak because I haven't done it in quite a few years.

Those bolts don't require thread lock, if the PO put some on then they screwed up.

After removing the forks then break the bottom bolt loose. An impact driver can help, but in my experience they usually break loose just using a regular ratchet. If they're buggered up then maybe the Torx idea will work if you're lucky. Otherwise it may be a case of drilling the head off and trying to extract the remaining screw from the fork lower. Also, the screws are recessed into the fork lower far enough that a regular length hex drive socket won't usually reach, so you'll need a long reach hex socket, or make one yourself. I think its 6mm hex drive, but my memory is weak because I haven't done it in quite a few years.

Those bolts don't require thread lock, if the PO put some on then they screwed up.

Yup, can attest to that.... Also, the screws are recessed into the fork lower far enough that a regular length hex drive socket won't usually reach, so you'll need a long reach hex socket, or make one yourself. I think its 6mm hex drive, but my memory is weak because I haven't done it in quite a few years.

Those bolts don't require thread lock, if the PO put some on then they screwed up.

My standard Craftsman 3/8" drive hex bits were too short to reach, so I went to Horrible Fright and bought some long reach hex bits. I think the drive had twisted a good 1/4 to 1/3 turn without budging the bolt - I was turning the shank of that bit into a Twizzler (or, gawd forbid, a Red Vine for the Left Coasters).

Fortunately those same Craftsman bits held the hex shank in place with a set screw, so I took a harden steel hex key, measured and cut it to length with my trusty Dremel and swap out the standard length with the longer one when the need arises.

Yet another reason why I refuse to buy mechanics' tools from 'that place'. I can easily afford to replace a garbage tool, but I have too many expensive things that can be rendered hot garbage by a cheap tool given the opportunity.

As for the thread lock, it's clearly indicated in the service manual.

As for the thread lock, it's clearly indicated in the service manual.

yeah, I've been replacing fork seals for 45 years on numerous bikes and never used it, the bolts have never budged.

Then when somebody puts Locktite red on it because they don't know any better, but they "saw it in the service manual" then the next person to deal with that screw will surely wish they hadn't bothered reading the manual.

Its an individual choice, personally I'd never use it because its solving a problem that doesn't exist. YMMV. My guess is its more of a legal CYA than a real mechanical need.

I'm not necessarily disagreeing with your service choice, just that Pete may have to contend with thread lock on the bolt during its disassembly!yeah, I've been replacing fork seals for 45 years on numerous bikes and never used it, the bolts have never budged.

Then when somebody puts Locktite red on it because they don't know any better, but they "saw it in the service manual" then the next person to deal with that screw will surely wish they hadn't bothered reading the manual.

Its an individual choice, personally I'd never use it because its solving a problem that doesn't exist. YMMV. My guess is its more of a legal CYA than a real mechanical need.

Now if I was popping mad woolies where I routinely get the wheel high enough off the pavement to allow the sliders to slip off the stanchions, then maybe I'd want that thread lock.

But seriously, from a practical standpoint. you're right. There's little chance of that bolt being an issue. That whole assembly is under compression and doesn't favor the bolt backing out. First sign might be fork oil weeping from around the axle at the bottom of the leg, and the axle will prevent it from going anywhere either.

I think your correct looks like they have been installed upside down the woes continueHmm, usually it is a very large nut, makes me wonder if the PO installed the fork caps upside down.

If you remove that, the 'guts' will want to push upward so be careful.

I also suggest you loosen it while the forks are still in the triple tree.

Otherwise trying to get a grip on the forks to hold them so you can loosen it is a bit of an 'interesting' situation.

Question could you fit forks that come from abs bike to non abs bikeHmm, usually it is a very large nut, makes me wonder if the PO installed the fork caps upside down.

If you remove that, the 'guts' will want to push upward so be careful.

I also suggest you loosen it while the forks are still in the triple tree.

Otherwise trying to get a grip on the forks to hold them so you can loosen it is a bit of an 'interesting' situation.

Uncle Phil

Site Supporter

Pre 96 ABSI maybe, 96 and later ABSII - no.Question could you fit forks that come from abs bike to non abs bike

ABSII has a different triple tree, different size forks (43mm) and the front calipers are different so the mounting point are different.

I have no idea if the caliper mounting points are the same between the ABSI and standard but the forks are the same size - 41mm.

Uncle Phil

Site Supporter

Since I gather that your bike is a non ABS, you should have 'innies' not 'outies' for fork caps.I think your correct looks like they have been installed upside down the woes continue

Share: