- Joined

- Mar 18, 2006

- Messages

- 2,867

- Age

- 70

- Location

- Ilkley, W Yorkshire, UK

- Bike

- 2013 ST1300 A9

- 2024 Miles

- 000679

- STOC #

- 2570

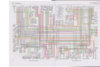

Re the circuit diagram above. I can understand why you have come to that conclusion from that section of the diagram. It is difficult to tell what is happening when you have just a small section of the diagram, which is why I teased out all if the important connections and relays and redrew them so that they could be read from left to right. The power has to come from a fused supply so I have put that on the left. @woodybelle says that is fuse L in the rear fuse box. I don't know, mine is a Uk bike so I have no way to verify.

The circuit finishes when the other end meets up with earth - the negative battery post.

But you can confirm that power is going into the ECM quite easily without having the ECM in place. Bike upright, ignition on. Check the voltage on the purple/black wire going into the bank angle relay. 12v ish. Now check the bk/white lead coming from the bank angle relay. That should be the same. All of those bk/wh leads are connected together. they should all read 12v ish. Including the ones that go to the ecm connector - although I have no idea how easy or difficult it is to probe those ecm terminals.

If any of those leads are dead then you have found the right area for your problem. Feed back - we can take it from there.

When you turn the kill switch off, they should all be dead.

I hope this does not sound as if I am being argumentative. I'm just trying to explain.

The circuit finishes when the other end meets up with earth - the negative battery post.

But you can confirm that power is going into the ECM quite easily without having the ECM in place. Bike upright, ignition on. Check the voltage on the purple/black wire going into the bank angle relay. 12v ish. Now check the bk/white lead coming from the bank angle relay. That should be the same. All of those bk/wh leads are connected together. they should all read 12v ish. Including the ones that go to the ecm connector - although I have no idea how easy or difficult it is to probe those ecm terminals.

If any of those leads are dead then you have found the right area for your problem. Feed back - we can take it from there.

When you turn the kill switch off, they should all be dead.

I hope this does not sound as if I am being argumentative. I'm just trying to explain.

Last edited: