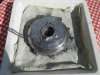

Today I installed that semi polished clutch cover plate, polished the slave pin, cleaned and greased the rubber seals to the slave and assembled those. After discovering that the slave line should have been brought around to the inside of the frame, prior to stuffing the engine in the frame, my simple solution was to unbolt the bango bolt at the slave and reroute it to the proper spot. Knowing I was going to spill a bit of brake fluid a catch pan prevented a messy spill. Back to the clutch reservoir I found a small pond had begun to sprout and cleaned it up before bleeding the system to the clutch slave. The motion pro tool came in handy bleeding the clutch line here, with a good clutch actuation at the lever. I cleaned the plastic timing belt covers with Meguiar's plastic restore. (left, before/right,after) Starter cables were installed, (frame to engine ground below) The red color on the clutch pin is Mobile 1 synthetic grease.