Checking my toolbox for an old rubber valve stem…rubber valve stem to fit/slide inside the banjo fitting

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Article [13] ST1300 - Brake Maintenance - Replacing the Secondary Master Cylinder (SMC)

- Thread starter jfheath

- Start date

-

- Tags

- 1300 brakes

NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER, NEVER

PINCH A BRAKE LINE.....WITH ANYTHING....REGARDLESS OF WHAT SOME CLOWN ON YOUTUBE SAID TO DO!

A rubber valve stem can be used, bonded washers with a bolt and wingnut can be used, heck a small piece of rubber tubbing with a bolt inserted through it can be used.

Don't worry about the air your gonna have to bleed the system correctly anyhow when your done.

PINCH A BRAKE LINE.....WITH ANYTHING....REGARDLESS OF WHAT SOME CLOWN ON YOUTUBE SAID TO DO!

A rubber valve stem can be used, bonded washers with a bolt and wingnut can be used, heck a small piece of rubber tubbing with a bolt inserted through it can be used.

Don't worry about the air your gonna have to bleed the system correctly anyhow when your done.

many many thanks to yourself and Larry for without this advice, It was becoming a absolutely nightmare. my hat of to you both. warmest regards CraigGlad you passed the MOT!

I've confused you. Sorry. You need to have a good picture in your head about how the brakes are connected. I'll put a link at the bottom of this post - it shows a series of diagrams to explain how fluid reaches each of the brakes and bleed points.

It sounds very much like the SMC bore isn't sealing - possibly been knocked out of shape. The description you gave is pretty much the same as the situation a friend had. He fitted a service kit and it continued to do the same thing. A new SMC fixed it. He sent me his old one, which I investigated and then took a hacksaw to expose the full length of the bore. There are photos of it somewhere on here.

The rear brake going hard when the front brake is applied when the bike is stationary ? I don't see how that can happen. The front brake lever operates the two outer pistons in the front caliper. Nothing else. I need to think about this

I can see how the rear pedal may dip slightly when the front brake is applied: If the rear pedal is pressed it operates the front and rear centre pistons. When the front lever is applied, the two outer pistons at the front operate. The two outer pistons have a greater combined braking for e than the sungle centre piston, so they squeeze the pads harder onto the disc - leaving the centre puston applying little pressure at all, so with the same pressure still on the brake pedal, the lever can push the centre piston out a little more - so the prdal dips a tiny bit.

Pretty pictures. Download the pdf in post"1

Article [13] - ST1300 - Brake Maintenance - Getting all the air out of the brake system | ST1300 Articles

A detailed look at the process of getting the air out of the Honda ST1300 brake lines. A sequence of diagrams of the brake circuits, colour coded to show which parts of the system are being accessed when each bleed valve is opened and explanations of where the trouble spots are. These are just...www.st-owners.com

Question……why do you have to even crack bolt 2 or 4 if just changing out SMC? With 1 and 3 removed from the SMC, won’t the caliper still come off?

Thanks so much for your write up and the help.

Thanks so much for your write up and the help.

jfheath

John Heath

Question……why do you have to even crack bolt 2 or 4 if just changing out SMC? With 1 and 3 removed from the SMC, won’t the caliper still come off?

Ah - I wondered if someone was going to ask that. It's so long ago I had to go and look to remind myself.

It's not because the caliper won't come off unless you do. I was describing what I would do, and I would take it off. In which case I'd rather do it at this stage when the caliper is held pretty firmly. This is so that you don't need to apply the full 34Nm and more to undo a bolt on an object which is very difficult to hold in your hand against the turning force. But that #2 banjo bolt has two hoses connected to it. One that you can see in the photo, the other is a very short length that connect it to the inlet port of the SMC - and the SMC side of it has got to be removed. It is the banjo bolt for the centre piston but the other arm has a short hose to the inlet of the SMC - which has got to come off. This leaves you with long hose with a hole in the middle flapping around near the tyres and brake disc. If you remove #1 and #2 , you can slip the end of that hose into a poly bag and let it drip into there.

So no - I don't think you do need to take off 2 and 4. But I don't know. I've always just taken them off - I like things away from the bike so that I can inspect and clean. And anyway I bought a bag of 100 copper washers. I'm going to make damn sure that I get my money's worth.

Thank you so much!!!! I really appreciate your time and response.

Ray

Ray

The usual format from me - Description, some useful photos and a few tips and tricks to help you to avoid the normal 'Doh!' moments -

- Like emptying all of the fluid out before realising that you wanted tomove the pistons out as far as possible;

- Like reftting everything before realising that you cannot get your torque wrench in to fasten the last bolt;

- Like checking that the new SMC has been greased under the boot and then discovering that you can't replace it properly.

Anyway - there is a sequence, but it is not intended that you follow it. Just read it through before tackling the job. You may find the information useful.

Feel free to download, save or print this.

And if I mention @Mellow he may put it into the articles section !

Hi. hanks for the PDF article, it's going to prove very useful when I come to replace my SMC. Just out of interest, can you remember the Gooodridge part number for the crush washers?

jfheath

John Heath

I bought these from demon-tweeks.com Buy Goodridge Copper Crush Washers | Demon Tweeks (demon-tweeks.com)

In 'Choose an Option', I selected 3/8 inch ID (-3)

Now -> 3/8 inch = 9.525mm - and these are for an M10 bolt - so I was a tad cancerned. But further down the page it says:

So I ordered the -03 (3/8" / 10mm ID) version.

I measured one of mine with a vernier scale caliper.

OD 14.48mm

ID 10.03mm

Thickness 1.1mm

And for some reason these 3/8" washers are much cheaper than the 10mm washers.

As you can see, I bought a bag of 100. At 24p each incl VAT, that's only £24.00 for the 100. I just like to have things like this in stock. I hate it when a job is held up for want of a few small components.

Produce code is GDR44516.

This could be the start of a very old joke:

Except that isn't the case. Mine fit and seal perfectly !

And although they are copper fitted to alloy, I have had no problem with galvanic corrosion. But I don't leave them untouched for years on end either. I bought them in Jan 2019. I have 75 left. So I must have had the front brake system apart twice in 4 years. Probably once when I bought them for a new SMC and once when I took the forks off to fit new fork seals.

In 'Choose an Option', I selected 3/8 inch ID (-3)

Now -> 3/8 inch = 9.525mm - and these are for an M10 bolt - so I was a tad cancerned. But further down the page it says:

So I ordered the -03 (3/8" / 10mm ID) version.

I measured one of mine with a vernier scale caliper.

OD 14.48mm

ID 10.03mm

Thickness 1.1mm

And for some reason these 3/8" washers are much cheaper than the 10mm washers.

As you can see, I bought a bag of 100. At 24p each incl VAT, that's only £24.00 for the 100. I just like to have things like this in stock. I hate it when a job is held up for want of a few small components.

Produce code is GDR44516.

This could be the start of a very old joke:

"You know those copper washers that you told me about ?"

"Yeah, I bought a bag of 100. Why"

"Well I bought some"

"Ok"

"But they didn't fit"

"Oh - thats funny, mine didn't fit either"

Except that isn't the case. Mine fit and seal perfectly !

And although they are copper fitted to alloy, I have had no problem with galvanic corrosion. But I don't leave them untouched for years on end either. I bought them in Jan 2019. I have 75 left. So I must have had the front brake system apart twice in 4 years. Probably once when I bought them for a new SMC and once when I took the forks off to fit new fork seals.

I bought these from demon-tweeks.com Buy Goodridge Copper Crush Washers | Demon Tweeks (demon-tweeks.com)

In 'Choose an Option', I selected 3/8 inch ID (-3)

Now -> 3/8 inch = 9.525mm - and these are for an M10 bolt - so I was a tad cancerned. But further down the page it says:

So I ordered the -03 (3/8" / 10mm ID) version.

I measured one of mine with a vernier scale caliper.

OD 14.48mm

ID 10.03mm

Thickness 1.1mm

And for some reason these 3/8" washers are much cheaper than the 10mm washers.

As you can see, I bought a bag of 100. At 24p each incl VAT, that's only £24.00 for the 100. I just like to have things like this in stock. I hate it when a job is held up for want of a few small components.

Produce code is GDR44516.

This could be the start of a very old joke:

"You know those copper washers that you told me about ?""Yeah, I bought a bag of 100. Why""Well I bought some""Ok""But they didn't fit""Oh - thats funny, mine didn't fit either"

Except that isn't the case. Mine fit and seal perfectly !

And although they are copper fitted to alloy, I have had no problem with galvanic corrosion. But I don't leave them untouched for years on end either. I bought them in Jan 2019. I have 75 left. So I must have had the front brake system apart twice in 4 years. Probably once when I bought them for a new SMC and once when I took the forks off to fit new fork seals.

Thanks for the info. I spoke to Goodridge today and he said that 44516 either -3 or 10mm should beOK. I just wanted to check that they would work OK. You can actually buy direct from them:

Search: 2 results found for "44516"

Goodridge high performance braided stainless steel car and motorcycle brake hoses, motorsport hose and fittings. Including a range of fluid transfer systems; fuel, oil, coolant , hydraulic for car and motorcycles, specialist one off projects or major projects for motorsport and beyond.

The SMC is on order along with new rubber boots.

I followed jfheath’s instructions and changed mine out with no problems apart from a couple of leaky crush washers. I used a syringe and tubing for the flush which worked great as I had no helper. I did one practice flush to remind me of the order and two real flushes. No problems thank Goodness. Thanks to jfheath.

My experience was similarly uneventful and successful... if you discount my failure to place a spacer between the front pads while I pumped the rear brake. Realized the error of my ways mear millimeters from popping the pistons out of the caliper and flooding my garage floor with DOT4 and really messing up my bleeding progress. Disaster averted!I followed jfheath’s instructions and changed mine out with no problems apart from a couple of leaky crush washers. I used a syringe and tubing for the flush which worked great as I had no helper. I did one practice flush to remind me of the order and two real flushes. No problems thank Goodness. Thanks to jfheath.

Where is everyone getting new SMC from. I can't find one anywhere and I'm in trouble without the partGlad you passed the MOT!

I've confused you. Sorry. You need to have a good picture in your head about how the brakes are connected. I'll put a link at the bottom of this post - it shows a series of diagrams to explain how fluid reaches each of the brakes and bleed points.

It sounds very much like the SMC bore isn't sealing - possibly been knocked out of shape. The description you gave is pretty much the same as the situation a friend had. He fitted a service kit and it continued to do the same thing. A new SMC fixed it. He sent me his old one, which I investigated and then took a hacksaw to expose the full length of the bore. There are photos of it somewhere on here.

The rear brake going hard when the front brake is applied when the bike is stationary ? I don't see how that can happen. The front brake lever operates the two outer pistons in the front caliper. Nothing else. I need to think about this

I can see how the rear pedal may dip slightly when the front brake is applied: If the rear pedal is pressed it operates the front and rear centre pistons. When the front lever is applied, the two outer pistons at the front operate. The two outer pistons have a greater combined braking for e than the sungle centre piston, so they squeeze the pads harder onto the disc - leaving the centre puston applying little pressure at all, so with the same pressure still on the brake pedal, the lever can push the centre piston out a little more - so the prdal dips a tiny bit.

Pretty pictures. Download the pdf in post"1

Article [13] - ST1300 - Brake Maintenance - Getting all the air out of the brake system | ST1300 Articles

A detailed look at the process of getting the air out of the Honda ST1300 brake lines. A sequence of diagrams of the brake circuits, colour coded to show which parts of the system are being accessed when each bleed valve is opened and explanations of where the trouble spots are. These are just...www.st-owners.com

jfheath

John Heath

I don't know which model you have - and it makes a difference. There is a white label on the frame under your seat which will say something likeWhere is everyone getting new SMC from. I can't find one anywhere and I'm in trouble without the part

ST1300A-9 or ST1300A-6 of ST1300-4 or ST1300A-4

That tells you the model type and the year. A means it is the version with ABS. The digit is the model year - that may be different from the registration / number plate year.

So my ST1300A9 is an ABS 2009 model (even though it was built in 2013)

I use Fowlers. They are fast, efficient, and when it isn't in stock they can get it from suppliers on the continent. Now thta parts are drying up and not many are being sold, the parts that are left tend to be held in fewer larger warehouses. But phone them - they will tell you exactly where they can get one from, how much and when it will be delivered. No point in shopping around in the UK - As I understand it, legally no one is allowed to sell Honda Parts cheaper.

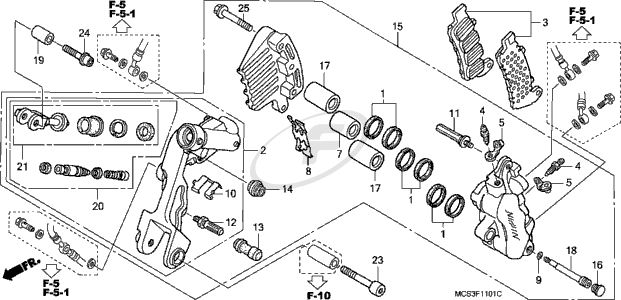

Part number 2 is the front left caliper for the ABS 2009 model. The ABS and non ABS models all use this part from 2008 to 2014.

L. FRONT BRAKE CALIPER - Honda ST1300A9 | Honda ST1300A9 2009 L. FRONT BRAKE CALIPER with fast delivery to United States | Fowlers Parts

Honda ST1300A9 | 2009 | All Colours | England | L. FRONT BRAKE CALIPER with fast delivery to United States. Available at Fowlers Parts, the UK's No.1 Motorcycle Parts Supplier.

The Fiche below is for the 2006 ABS model. Again part number 2. This same part is used on all ABS and non ABD from 2002 up to 2006. THis one is currently in stock.

L. FRONT BRAKE CALIPER - Honda ST1300A6 | Honda ST1300A6 2006 L. FRONT BRAKE CALIPER with fast delivery to United States | Fowlers Parts

Honda ST1300A6 | 2006 | All Colours | England | L. FRONT BRAKE CALIPER with fast delivery to United States. Available at Fowlers Parts, the UK's No.1 Motorcycle Parts Supplier.

The part number differ by one letter - R or G. That letter makes a lot of difference - even thought hey look identical in the parts diagram.

Note the banner at the top of the fiche. That gives you an idea of the words that you have to click on in ordert o find the correct fiche. This part is under L. Front Brake Caliper

Share: