So here is part of the document in question. This is a spec that is suppose to have usable values. In the table there are a bunch of zero values, so the only thing that is useful is the window values but they are not useful....... Where is the joke?...

hint: There is an old expression about minding your p's and q's. Solve the algebra.....

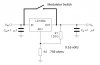

The drawing is an isometric view, which makes some of the dimensions referenced to points in space.

If it were drawn as a flat view it would be much simpler. Let me explain.

It looks like the two filaments are both skewed but as it turns out the low beam is centered and "h" is really zero.

then "g" the offset of the high beam is -12 mills. It can not be zero nor could it be positive. but the "g" tolerance is +/-...

Now I am a bit ahead, What is missing is the rotation spec. It is only alluded to by the isometric view.

So I have measured the rotation to be 10 degrees. What is rotated? it is the wire frame.

grab a H4 bulb and look at the back of it with the top tab straight up the glass bulb away from you.

look at the top tab and tilt up the bulb. you should see that the shield pan is not perpendicular to the top tab.

rotate the bulb 10 degrees CW to line up the wire frame. Now the shield pan is perpendicular to the frame and the filaments are in line with the frame. That is there is no skew..... look at the filaments relative to the wire frame... now you know.

There are other drawing mistakes. Now, if I am wrong please let me know.......