Yes, it should be free to move fairly easily if the brake pads and pistons were not restraining it. As an exaggeration to make the point, if the pistons were fully retracted and the pads were not installed, you should be able to easily slide the caliper back and forth along the sliders with minimal hand force.

I think that you are mixing up terminology. Are you referring to item #18 in the below diagram? If so, this is the hanger pin. This pin goes through the eyelets in the rear of the pads to hold them in place. This is not a slider pin.

There are two slider pins on which the caliper can move in and out relative to the brake disc. They are items # 13 and 14. They must be clean and have a light coating of silicone grease applied to them, as should the rubber parts that they fit in to.

The O-ring on the end of that pin, and its receptacle, should be clean and lubricated with rubber friendly brake grease. The body of this pin should be clean and free of scale so that the pads can slide on it, but I do not apply grease to it because it only causes the brake dust and road grime to stick to it making things worse.

Yes, all the same. Go to your local auto parts store and ask them for silicone brake grease for the rubber parts of the braking system. They will know what you are looking for. Automotive brake grease and motorcycle brake grease are the same. One can is not expensive and it will last your life-time.

The brake pad springs and retainers clips should not have grease applied to them for the same reason as above- it causes the brake dust and road grime to stick to them making things worse. If they are in bad shape, replace them. I know that John recommends it in his document, but that it because he is battling specific UK road environmental conditions that wreak havoc on exposed metal. Honda does not call for grease in these areas. If any lubricant is applied it can't be silicone grease as it will not survive there. Brake anti-seize for the metal parts of braking systems can be used if you feel the need. Again, your local auto parts will have it. I do not apply anything.

I do not apply anything to the back of the brake pads either. Again, just collects the dirt and grime. I have never felt the need for it.

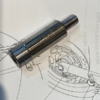

The exposed part of the pistons can be greased with the same silicone brake grease.

The other chemical that John mentions is to adhere the pad retainers to the caliper body. This is not a grease, it is a rubber adhesive that adheres the retainer to the caliper body.